Vibrating screens are suitable for various screening operations such as heavy, medium, and fine screening. It is not only an ideal screening equipment for processing the products after primary crushing and secondary crushing, but also can be used for final product screening.

Our vibrating screens are used in quarries to screen stone and facilitate product classification in coal preparation, mining, construction, and other industries.

Whether it is a circular vibrating screen or a linear vibrating screen, they all have the characteristics of multi-layer, high screening efficiency, and various screening specifications.

Get Latest PriceThe vibrating screen can handle various materials, including minerals (granite, gold ore, pebble, limestone, etc.), construction waste, glass, slag, concrete, cement clinker, and other materials.

| Model | Max.Feeding Size (mm) | Processing capacity(t/h) |

| 2HX1545 | 200 | 45-500 |

| 3HX1545 | 200 | 55-500 |

| 4HX1545 | 200 | 65-500 |

| 2HX1855 | 200 | 55-600 |

| 3HX1855 | 200 | 65-600 |

| 4HX1855 | 200 | 75-600 |

| 2HX2165 | 200 | 65-700 |

| 3HX2165 | 200 | 75-700 |

| 4HX2165 | 200 | 85-700 |

| 2HX2465 | 200 | 80-800 |

| 3HX2465 | 200 | 90-800 |

| 4HX2465 | 200 | 100-800 |

| 2HX2765 | 200 | 100-900 |

| 3HX2765 | 200 | 110-900 |

| 4HX2765 | 200 | 120-900 |

| 2HX3065 | 200 | 110-1200 |

| 3HX3065 | 200 | 120-1200 |

| 4HX3065 | 200 | 130-1200 |

| 2HX3075 | 300 | 120-1300 |

| 3HX3075 | 300 | 130-1300 |

Note:processing Capacity May Vary With Different Materials And Feeding Sizes.

| Model | Sieve layer |

Mesh size |

Feeding size |

Processing capacity |

| (mm) | (mm) | (t/h) | ||

| ZSG1237 | 1 | 4-50 | ≤200 | 10-100 |

| 2ZSG1237 | 2 | 4-50 | ≤200 | 10-100 |

| ZSG1443 | 1 | 4-50 | ≤200 | 10-150 |

| 2ZSG1443 | 2 | 4-50 | ≤200 | 10-150 |

| 3ZSG1443 | 3 | 4-50 | ≤200 | 10-150 |

| 2ZSG1548 | 2 | 5-50 | ≤200 | 15-200 |

| 3ZSG1548 | 3 | 5-50 | ≤200 | 15-200 |

| 2ZSG1848 | 2 | 5-50 | ≤300 | 50-500 |

| 3ZSG1848 | 3 | 5-50 | ≤300 | 50-500 |

| 4ZSG1848 | 4 | 5-50 | ≤200 | 50-500 |

| 2ZSG1860 | 2 | 5-150 | ≤300 | 80-600 |

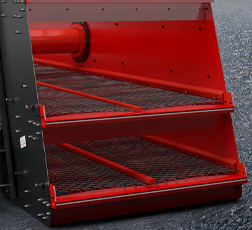

Materials of various particle sizes are placed on the screen. Change the eccentric axis of the exciter. Can cause the screen to obtain different amplitudes. Large-sized materials remain at the top, while small materials pass through the screen holes to the bottom, thereby completing coarse and fine screening.

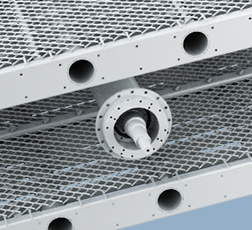

The vibrator has an eccentric shaft and eccentric block structure. The amplitude, frequency, and inclination angle can be adjusted arbitrarily. The vibration intensity is as high as 5.0G, and the screening efficiency is high.

We provide screens with different materials (high manganese steel woven screens, punched screen plates, rubber screen plates, etc.), number of layers (1–4 layers), and sizes (3–150 mm). It is not easy to block, has large output, and can meet different screening effects.

The vibrating screen has a simple structure and uses carbon steel mesh, anti-corrosion bearings and thin oil bath lubrication, which can greatly extend its service life.

We collaborate with clients globally to deliver top-notch mineral processing equipment and tailored solutions, aiming to optimize plant efficiency and reduce operating costs. Additionally, we prioritize ESG (Environmental, Social, and Governance) initiatives, actively advocating for the sustainable advancement of eco-friendly mining and recycling sectors.

Based on high quality and perfect after-sales service, our products have been exported to more than 120 countries and regions. FTM Machinery has become the first choice of more than 2,000,000 customers.