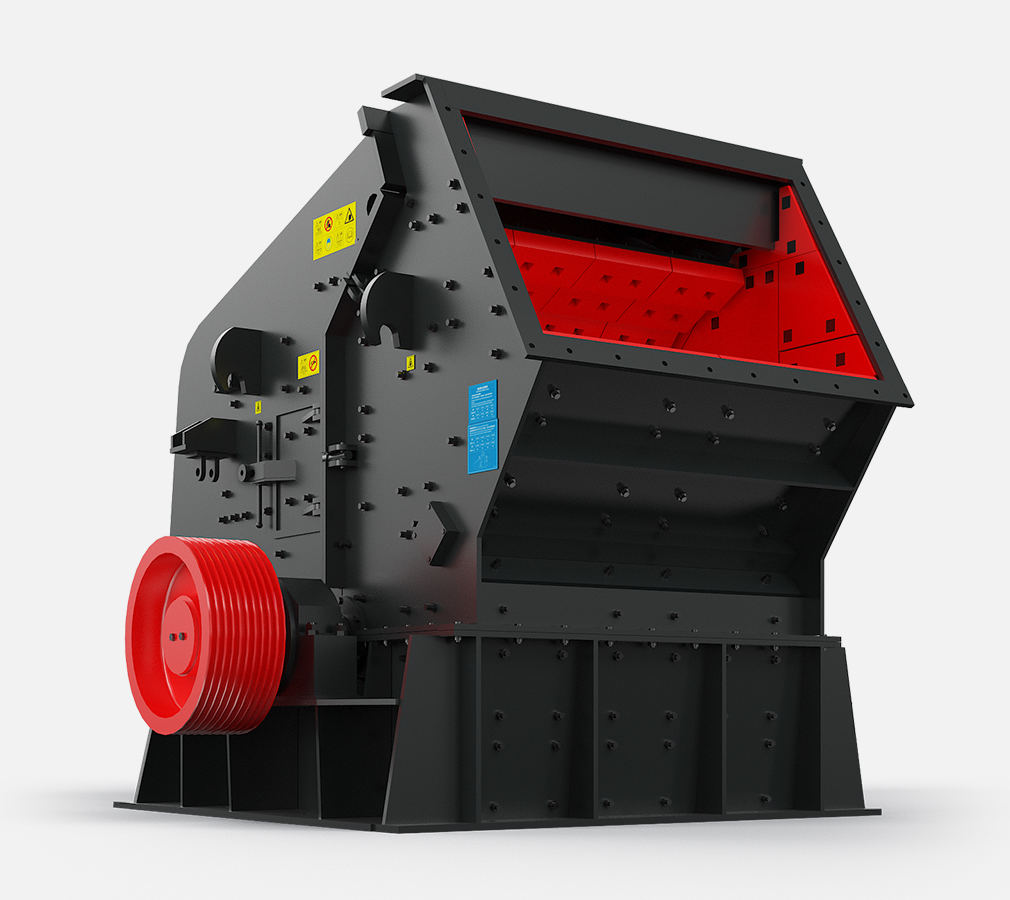

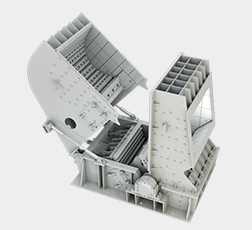

Designed for increased profitability, our impact crushers combine cutting-edge impact crushing technology with rugged design. It optimizes the rotor and crushing chamber to achieve higher crushing rates with fewer crushing stages.

Impact crushers usually form a complete crushing system with jaw crushers and are suitable for railways, highways, airports, cement, chemicals, construction and industries that require cubic-shaped rocks.

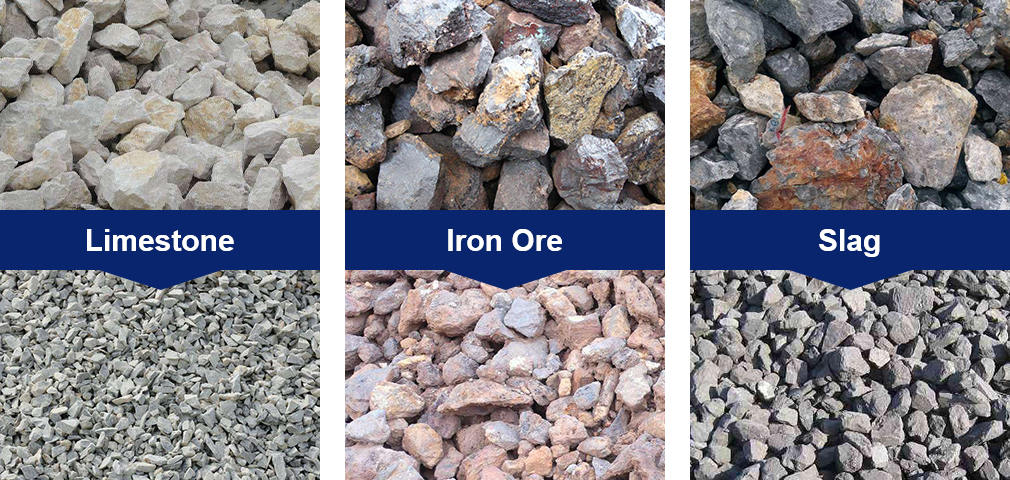

Get Latest PriceThe impact crusher can perform secondary and tertiary crushing of materials with a compressive strength not exceeding 350 MPa. It is suitable for limestone, granite, basalt, cobblestone, gold ore, chrome ore, iron ore, gypsum, glass, cement, concrete, asphalt, slag, construction waste, etc.

| Model | Feed Opening (mm) | Max.Feeding Size (mm) | Capacity (t/h) |

| PF-1007 | 400×730 | 300 | 30-70 |

| PF-1010 | 400×1080 | 350 | 50-90 |

| PF-1210 | 400×1080 | 350 | 70-130 |

| PF-1214 | 400×1430 | 350 | 80-180 |

| PF-1315 | 860×1520 | 500 | 100-280 |

| PF-1320 | 993×20000 | 500 | 140-380 |

| PF-1520 | 830×2040 | 700 | 200-550 |

| PF-1820 | 1260×2040 | 800 | 300-800 |

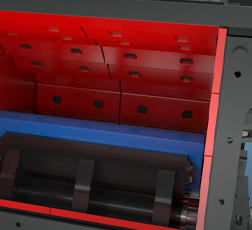

Impact crushers use energy from impacts to crush materials. A high-speed rotor driven by an electric motor crushes material entering the cavity through a feed port. The crushed material undergoes secondary crushing by striking the impact plate at high speed until it reaches the desired particle size and is discharged from the outlet.

With a large feed inlet and high crushing chamber, it's ideal for processing large hard materials with low powder.

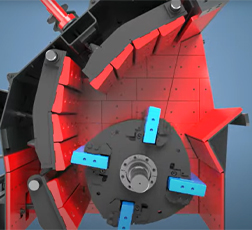

Features an oversized, sturdy rotor and cavity, optimizing rotation speed and power for increased output and crushing ratio. Suited for coarse, medium, fine crushing, and recycling

Equipped with wear-resistant high-chromium blow hammer and a unique locking system, along with a high-quality welded structure for enhanced performance and lifespan. Modular design reduces part consumption, extends replacement cycle, and saves costs.

We collaborate with clients globally to deliver top-notch mineral processing equipment and tailored solutions, aiming to optimize plant efficiency and reduce operating costs. Additionally, we prioritize ESG (Environmental, Social, and Governance) initiatives, actively advocating for the sustainable advancement of eco-friendly mining and recycling sectors.

Based on high quality and perfect after-sales service, our products have been exported to more than 120 countries and regions. FTM Machinery has become the first choice of more than 2,000,000 customers.