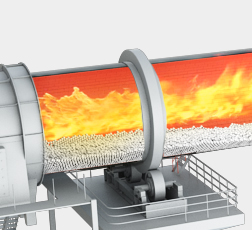

The rotary kiln, known also as the rotary calcination kiln, is a gently inclined rotating cylindrical furnace. Through continuous calcination or sintering of solid materials, it induces chemical reactions or phase alterations.

According to different materials processed, rotary kilns can be divided into three types:

◎ Cement kiln: Used for calcining cement clinker in dry and wet cement plants, such as limestone, clay, gypsum, shale, etc.

◎ Metallurgical chemical kiln: Used for lean iron ore, nickel iron ore, bauxite, lithium ore, chromium ore, nickel iron ore, magnesite,and ceramsite in steel plants, chemical plants and refractory material plants.

◎ Lime kiln: Used for roasting activated limestone and light burnt dolomite in steel plants, ferroalloy plants and magnesium plants.

Get Latest PriceCement clinker, limestone, clay, slag, bauxite, dolomite, lithium ore, ceramsite (LECA), gypsum, chromium ore, nickel iron ore, zinc oxide, phosphate fertilizer, barium sulfide, etc.

| Product Specification (m) |

Capacity (t/d) |

Rotation speed (r/min) |

| Φ2.5×40 | 180 | 0.44-2.44 |

| Φ2.5×50 | 200 | 0.62-1.86 |

| Φ2.5×54 | 280 | 0.48-1.45 |

| Φ2.7×42 | 320 | 0.10-1.52 |

| Φ2.8×44 | 450 | 0.437-2.18 |

| Φ3.0×45 | 500 | 0.5-2.47 |

| Φ3.0×48 | 700 | 0.6-3.48 |

| Φ3.0×60 | 800 | 0.3-2 |

| Φ3.2×50 | 1000 | 0.6-3 |

| Φ3.3×52 | 1300 | 0.266-2.66 |

| Φ3.5×54 | 1500 | 0.55-3.4 |

| Φ3.6×70 | 1800 | 0.25-1.25 |

| Φ4.0×56 | 2300 | 0.41-4.07 |

| Φ4.0×60 | 2500 | 0.396-3.96 |

| Φ4.2×60 | 2750 | 0.41-4.07 |

| Φ4.3×60 | 3200 | 0.396-3.96 |

| Φ4.5×66 | 4000 | 0.41-4.1 |

| Φ4.7×74 | 4500 | 0.35-4 |

| Φ4.8×74 | 5000 | 0.396-3.96 |

| Φ5.0×74 | 6000 | 0.35-4 |

| Φ5.6×87 | 8000 | Max4.23 |

| Φ6.0×95 | 10000 | Max5 |

The rotary kiln is a tilted cylinder that rotates slowly, moving raw materials from high to low end for chemical reactions. Heat from pulverized coal combustion at the kiln head aids in material decomposition, forming clinker discharged from the lower end.

The rotary kiln has high refractoriness and can operate at temperatures exceeding 850°C without softening, ensuring long-term operation. It also has good wear resistance and flexural strength, allowing the kiln body to withstand maximum stress without cracking.

It features a fully automatic control system adjusting heating temperature, rotation speed, and axial movement for precise operation.

It offers three heating methods for even distribution and 20% lower heat consumption, enhancing energy efficiency.

The rotary kiln has a high production capacity (150–10,000 tons per day), stable clinker quality, and high economic benefits

We collaborate with clients globally to deliver top-notch mineral processing equipment and tailored solutions, aiming to optimize plant efficiency and reduce operating costs. Additionally, we prioritize ESG (Environmental, Social, and Governance) initiatives, actively advocating for the sustainable advancement of eco-friendly mining and recycling sectors.

Based on high quality and perfect after-sales service, our products have been exported to more than 120 countries and regions. FTM Machinery has become the first choice of more than 2,000,000 customers.