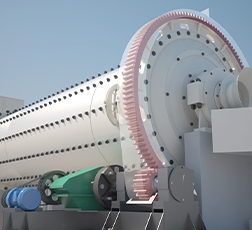

The ball mill is a grinding machine that finely grinds materials smaller than 25 mm to 20-200 mesh through dry grinding and wet grinding. Wet operations are usually equipped with classifiers and dry operations with dust collectors.

The ball mill is suitable for primary and secondary grinding stages, working together with the crushers and mineral processing equipment during the mineral processing process.

Get Latest PriceThe ball mill can grind metal ores, non-metallic ores, cement clinker, slag, quartz sand, zircon sand, glass, ceramics, new building materials, etc.

| Model | Feeding size (mm) |

Capacity (t/h) |

| Ф900×1800 | <20 | 0.65-2 |

| Ф900×3000 | <20 | 1.1-3.5 |

| Ф1200×2400 | <25 | 1.5-4.8 |

| Ф1200×3000 | <25 | 1.6-5 |

| Ф1200×4500 | <25 | 1.6-5.8 |

| Ф1500×3000 | <25 | 2-5 |

| Ф1500×4500 | <25 | 3-6 |

| Ф1500×5700 | <25 | 3.5-6 |

| Ф1830×3000 | <25 | 4-10 |

| Ф1830×4500 | <25 | 4.5-12 |

| Ф1830×6400 | <25 | 6.5-15 |

| Ф1830×7000 | <25 | 7.5-17 |

| Ф2100×3000 | <25 | 6.5-36 |

| Ф2100×4500 | <25 | 8-43 |

| Ф2100×7000 | <25 | 12-48 |

| Ф2200×4500 | <25 | 9-45 |

| Ф2200×6500 | <25 | 14-26 |

| Ф2200×7000 | <25 | 15-28 |

| Ф2200×7500 | <25 | 15-30 |

| Ф2400×3000 | <25 | 7-50 |

| Ф2400×4500 | <25 | 8.5-60 |

| Ф2700×4000 | <25 | 22-80 |

| Ф2700×4500 | <25 | 26-90 |

| Ф3200×4500 | <25 | As per process conditions |

| Ф3600×4500 | <25 | As per process conditions |

| Ф3600×6000 | <25 | As per process conditions |

| Ф3600×8500 | <25 | 45.8-256 |

| Ф4000×5000 | <25 | 45-208 |

| Ф4000×6000 | <25 | 65-248 |

| Ф4000×6700 | <25 | 75-252 |

| Ф4500×6400 | <25 | 84-306 |

| Ф5030×6400 | <25 | 98-386 |

| Ф5030×8300 | <25 | 118-500 |

| Ф5500×8500 | <25 | 148-615 |

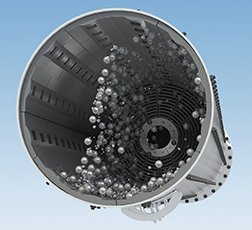

Material enters through feeding device into the mill, lined with wear-resistant plates and grinding balls. Cylinder rotation creates centrifugal force, lifting balls to impact and grind material. Powdery material exits through discharge port, completing grinding process.

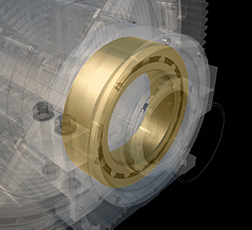

The mill features a straightforward structure, operates hydraulically, and is easy to maintain, enhancing operational efficiency and reducing downtime for maintenance tasks.

Offering a large output capacity, the mill can operate intermittently or continuously, catering to various production needs with flexibility.

With fine and uniform output size, the mill ensures consistent product quality, meeting desired specifications consistently.

Wear-resistant cylinder and grinding balls, along with selectable liner plates, ensure durability. Additionally, the closed grinding system with a classifier minimizes dust and noise pollution, promoting an environmentally friendly operation.

We collaborate with clients globally to deliver top-notch mineral processing equipment and tailored solutions, aiming to optimize plant efficiency and reduce operating costs. Additionally, we prioritize ESG (Environmental, Social, and Governance) initiatives, actively advocating for the sustainable advancement of eco-friendly mining and recycling sectors.

Based on high quality and perfect after-sales service, our products have been exported to more than 120 countries and regions. FTM Machinery has become the first choice of more than 2,000,000 customers.