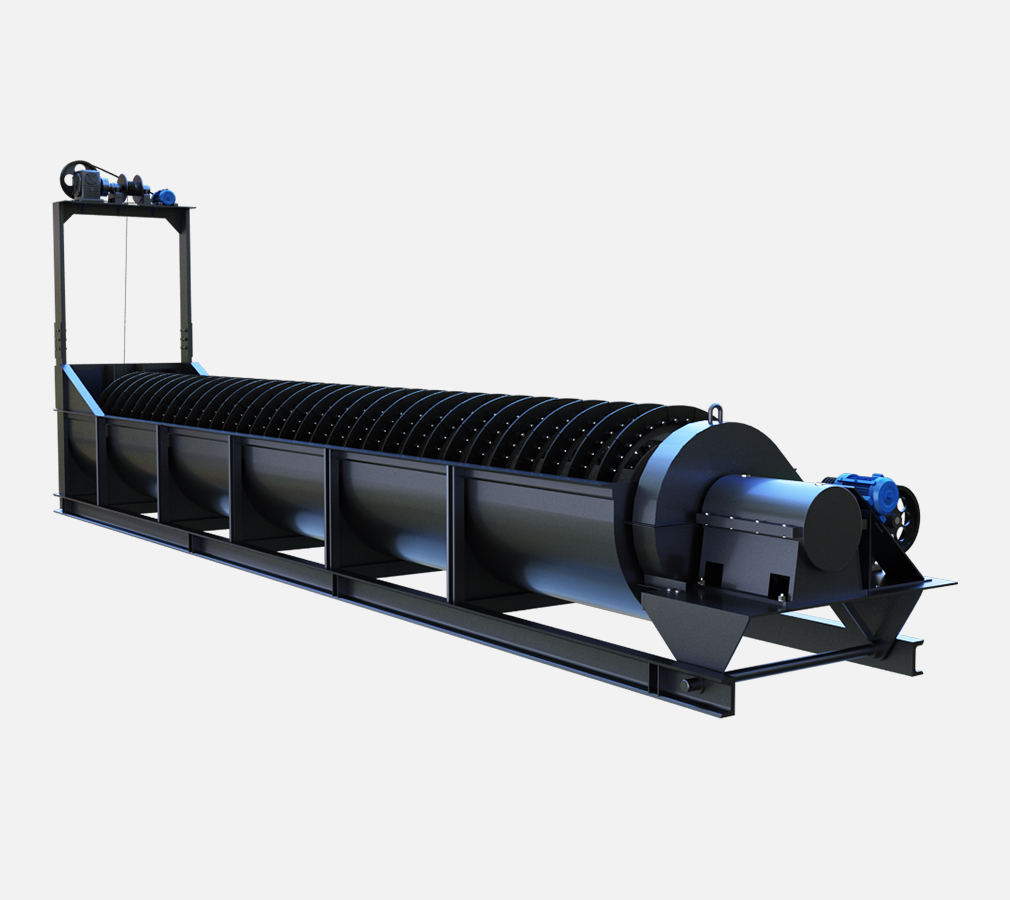

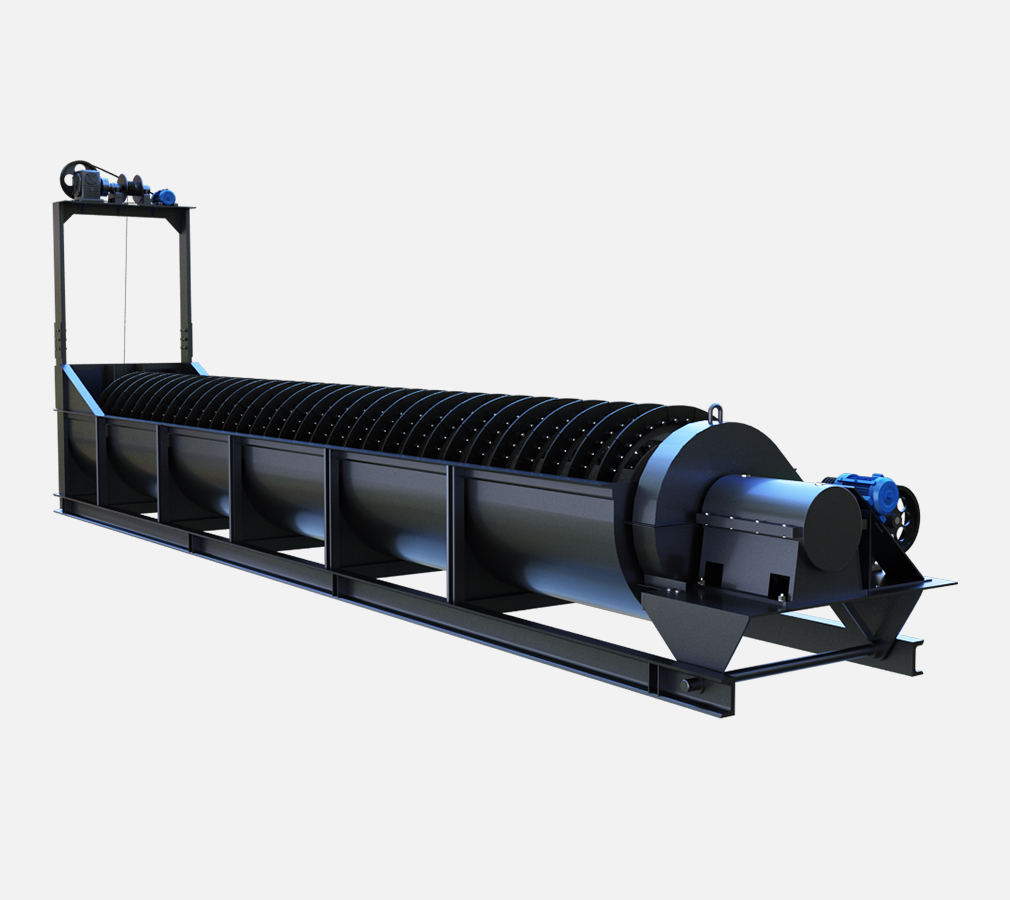

The spiral classifier is commonly used in mineral processing plants to classify slurry particles in closed circulation with the ball mill. It is also effective in washing, desliming, and dehydrating sand in large and medium dry sand making plants.

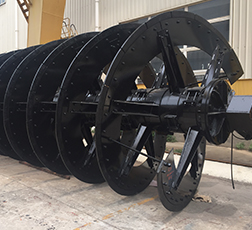

Spiral classifiers are divided into single spiral classifiers and double spiral classifiers. According to the procedure of how deeply the spiral blades at the overflow end are immersed in the overflow surface, they can be further divided into high weir classifiers and immersed classifiers.

Get Latest PriceThe spiral classifier can classify, wash and deslime materials suitable for wet ball mills. Its applicable materials are metal ores (such as gold ore, iron ore, copper ore), non-metallic ores (such as quartz, gypsum, cobblestone), cement clinker, etc. with an overflow particle size of 25 to 90.

| Model | Spiral Diameter (mm) |

Spiral rotate speed (r/min) |

| FG-3 | 300 | 12-30 |

| FG-5 | 500 | 8-12.5 |

| FG-7 | 750 | 6-10 |

| FG-10 | 1000 | 5-8 |

| FC-10 | ||

| FG-12 | 1200 | 4-6 |

| FC-12 | ||

| 2FG-12 | ||

| 2FC-12 | ||

| FG-15 | 1500 | 4-6 |

| FC-15 | ||

| 2FG-15 | ||

| 2FC-15 | ||

| FG-20 | 2000 | 3.6-5.5 |

| FC-20 | ||

| 2FG-20 | ||

| 2FC-20 | ||

| FG-24 | 2400 | 3.67 |

| FC-24 | ||

| 2FG-24 | ||

| 2FC-24 | ||

| 2FG-30 | 3000 | 3.2 |

| 2FC-30 |

The spiral separator sorts materials by the speed at which solid particles settle in liquid. It sifts crushed powder from the mill, with fine particles flowing over and coarse ones settling at the tank bottom. Coarse particles return to the mill for further grinding, completing a closed circuit with the spiral classifier and ball mill.

The equipment features a simple structure and frequency conversion control for ease of operation.

The quality of stone powder is easy to control, and the content of 0.00–0.75 mm stone powder is adjustable between 2% and 15%.

The design incorporates appropriate pulp tank depth, area, and spiral structure, facilitating efficient grading control.

It is lined with tiles and has low maintenance rate. The base is made of channel steel and the machine body is welded with steel plates, which has good quality and high wear resistance.

It is lined with tiles and has low maintenance rate. The base is made of channel steel and the machine body is welded with steel plates, which has good quality and high wear resistance.

Additionally, we prioritize ESG (Environmental, Social, and Governance) initiatives, actively advocating for the sustainable advancement of eco-friendly mining and recycling sectors.

Based on high quality and perfect after-sales service, our products have been exported to more than 120 countries and regions. FTM Machinery has become the first choice of more than 2,000,000 customers.