Jaw crusher is a primary crusher that is widely used in crushing circuits, providing better crushing solutions for mining, smelting, building materials, highways, railways, water conservancy, chemical industry and other industries.

Thousands of our jaw crushers are installed around the world and demonstrate excellent performance in aggregate crushing, mineral processing and recycling. It has superior crushing capacity, a crushing ratio of 3-6, and uniform product particle size, which can meet large-scale crushing needs.

Get Latest PriceThe compression strength of the materials to be crushed is less than 320 MPa.

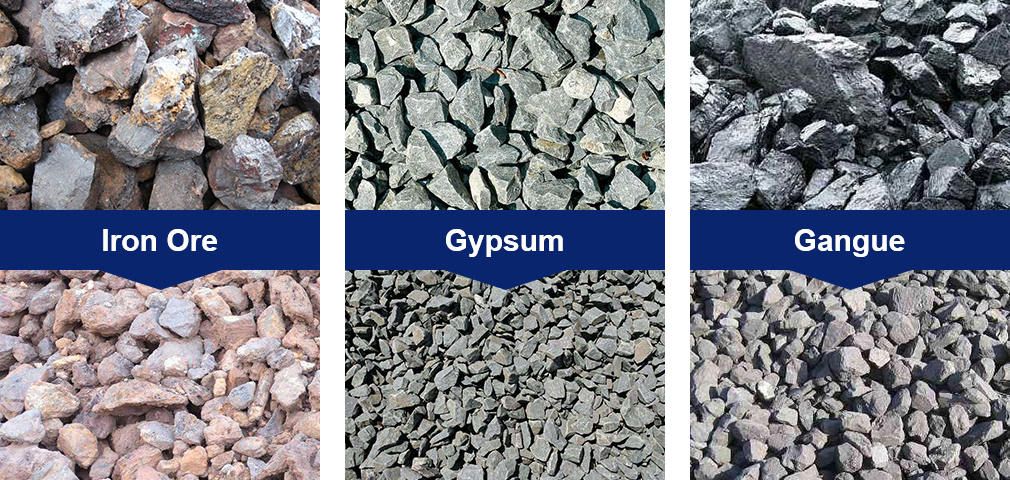

Whether it is metal ores (gold ore, iron ore, etc.), non-metallic ores (quartz, limestone, gypsum, etc.), rocks (granite, basalt, etc.), gangue, concrete, construction waste , glass, or cement clinker, our jaw crushers can easily crush it.

| Model | Max.Feeding size (mm) | Capacity (t/h) |

| PE 150×250 | 125 | 1-3 |

| PE 200×300 | 180 | 2-6 |

| PE 200×350 | 180 | 3-10 |

| PE 250×400 | 210 | 5-21 |

| PE 400×600 | 340 | 16-64 |

| PE 500×750 | 425 | 40-110 |

| PE 600×750 | 500 | 80-240 |

| PE 600×900 | 500 | 50-160 |

| PE 750×1060 | 630 | 110-320 |

| PE 900×1200 | 750 | 220-380 |

| PE 1200×1500 | 1020 | 400-1000 |

| PE 1500×1800 | 1200 | 500-1200 |

| PEX 150×750 | 120 | 8-25 |

| PEX 250×750 | 210 | 13-35 |

| PEX 250×1000 | 210 | 16-52 |

| PEX 250×1200 | 210 | 20-61 |

| PEX 300×1300 | 250 | 16-105 |

Note:processing Capacity May Vary With Different Materials And Feeding Sizes.

| Model | Feeding opening size(mm) | Max.Feeding size(mm) | Capacity (t/h) |

| HD72(57) | 460×720 | 425 | 50-120 |

| HD86(69) | 580×860 | 500 | 60-280 |

| HD98(751) | 680×980 | 630 | 110-410 |

| HD110(912) | 850×1100 | 750 | 170-550 |

| HD125 | 950×1250 | 900 | 280-750 |

Note:processing Capacity May Vary With Different Materials And Feeding Sizes.

| Model | Maximum Feeding size(mm) | Capacity(t/h) |

| CJ96 | 480 | 105-390 |

| CJ106 | 560 | 150-500 |

| CJ120 | 700 | 175-610 |

| CJ125 | 760 | 270-831 |

| CJ150 | 960 | 340-880 |

| CJ160 | 960 | 430-1145 |

| CJ200 | 1200 | 630-1435 |

| CJ1511 | 850 | 425-1195 |

| CJ1513 | 1040 | 530-1280 |

Note:processing Capacity May Vary With Different Materials And Feeding Sizes.

Our version at FTM Machinery is to offer full flowsheet technology for mining, construction, recycling, agriculture, and other industries. We also provide after-sales services to international markets.

Our commitment is to establish an unwavering reputation for reliability and to play a significant role in driving a better world as a top global industry brand.

Deep crushing cavity with no dead corners improves feeding and output efficiency.

Large crushing ratio ensures uniform particle size for optimal results.

Welded fixed steel structure, large bearings, and forged spindle enhance bearing capacity, ensuring durability and reliability. Unique flywheel design minimizes vibration, providing stable operation.

Wide adjustment range of discharge port via gaskets meets various particle size requirements of customers. Simple structure and centralized lubrication system facilitate easy operation and maintenance.

Wear-resistant materials used in jaw plates extend service life. Significantly reduces dust and noise levels while lowering energy consumption by 15%-30%.

We collaborate with clients globally to deliver top-notch mineral processing equipment and tailored solutions, aiming to optimize plant efficiency and reduce operating costs. Additionally, we prioritize ESG (Environmental, Social, and Governance) initiatives, actively advocating for the sustainable advancement of eco-friendly mining and recycling sectors.

Based on high quality and perfect after-sales service, our products have been exported to more than 120 countries and regions. FTM Machinery has become the first choice of more than 2,000,000 customers.